FOX – Food processing in a Box – is a project that aims to transform large-scale technologies for the processing of fruits and vegetables, to small, flexible and mobile container units. The project focuses on mild processing technologies, such as low-temperature drying and mild preservation techniques, to achieve the optimal physical and nutritional quality of fruit and vegetable products. So-called Food Circles have been defined, these are European regions with significant fruit and vegetable production where specific FOX technologies will be demonstrated. In these regions, the impact of the FOX approach on the environment, business, people and their health will be assessed.That, together with the input from engaged consumers, will serve as vital information for the further development and upscaling of FOX.

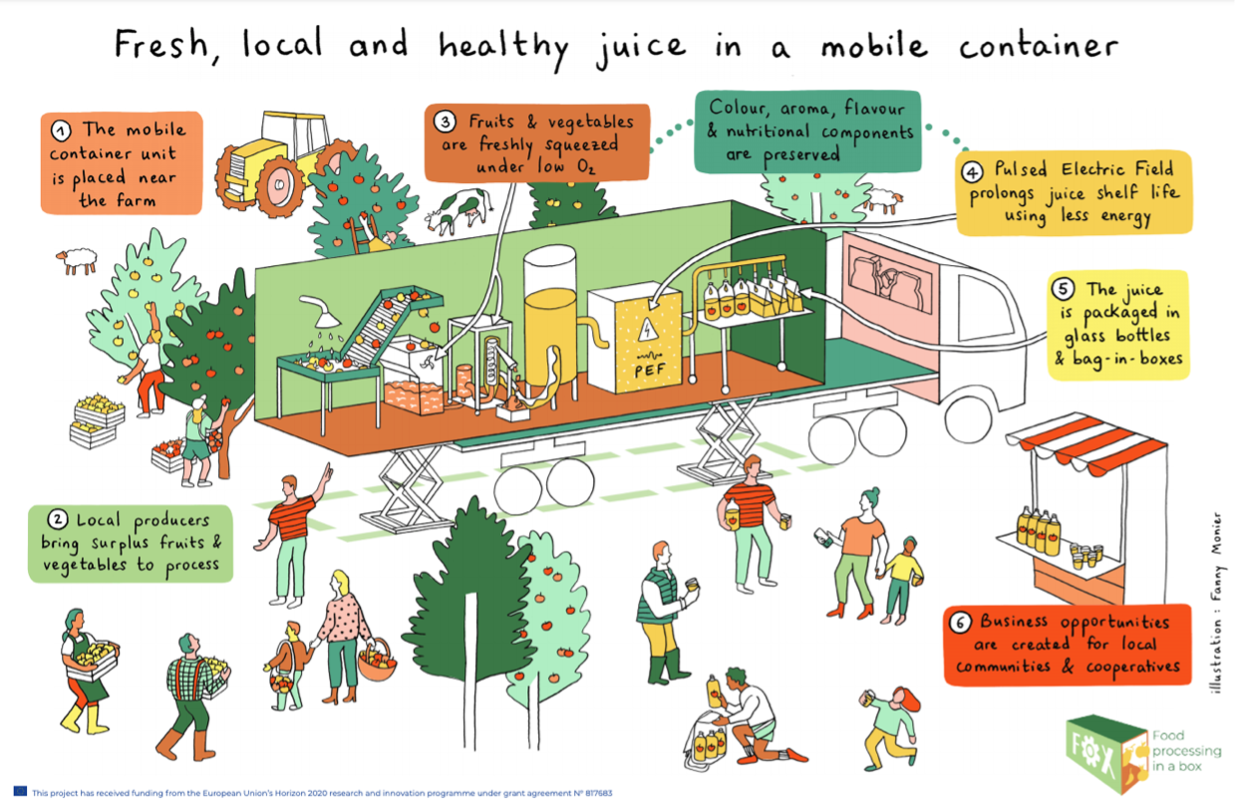

Food Circle 1: Low oxygen juice extraction and mild preservation

During the harvest period, the mobile processing unit at the farm will process a peak amount of fruits without quality loss. High-quality fruit/puree production will be achieved with downscaled, innovative technologies for low oxygen juice/puree extraction and low heat preservation.

This Food Circle aims to develop a small-scale mobile processing unit, that will enable:

- High-quality fruit juices and puree production

- Flexible production for different types of fruits

- Practical and simple installation and operation on the farm(s)

Prototypes of small-scale juice production units will be tested for feasibility and practicability at farms in the Lake Constance (Bodensee) region in Germany.

Food Circle 2: Low temperature drying

Soft fruits, vegetables and mushrooms often cannot be served as ready to eat food. Drying of fruits and vegetables can be a valuable alternative for farmers when the economic situation is not favourable for direct sale of the fresh products.

This Food Circle aims to:

- Add value to fruit and vegetable products

- Open new business opportunities for farmers

- Manage the surplus of crops/produces

The mild drying units will be tested in the Central Bohemian Region in the Czech Republic and/or Kuyavian-Pomeranian Voivodeship region in Poland.

Food Circle 3: Quality analysis and sustainable packaging

Fresh-cut products need packaging adapted to their specific breathing activity to extend shelf life. To avoid environmental problems related to packaging ecodesign principles will be applied.

This Food Circle aims to:

- Design a mobile unit to select, process and package fresh-cut fruit and vegetable products

- Develop sustainable packaging to enlarge the shelf life of fresh-cut fruit and vegetable products

- Provide fresh-cut fruit and vegetable snacks produced by local producers

- Encourage the consumption of fresh fruit and vegetables

The packaging units will be tested in Valencia, Spain and Alpes Côte d’Azur, France.

Food Circle 4: Upscaling plant side streams

Food-graded side streams usually turn into non-food grade streams. One way to avoid this, is to immediately further process these streams towards more sustainable options: ingredients, food products or feed. For this purpose, a number of mild processing technologies will be further developed including high pressure, Pulse Electric Field (PEF), supercritical CO2 and mild thermal technologies.

This Food Circle aims to

- Optimise vegetable-based food side streams

- Create high-quality food products and ingredients via mild processing technologies

- Develop pre-processing technologies for side streams

The processing concepts for plant-based side streams will be tested in field labs in Noord-Brabant, the Netherlands.

Visit the FOX wesbite, for more information on the Food Circles and sign up for the FOX newsletter to stay up to date on project developments.